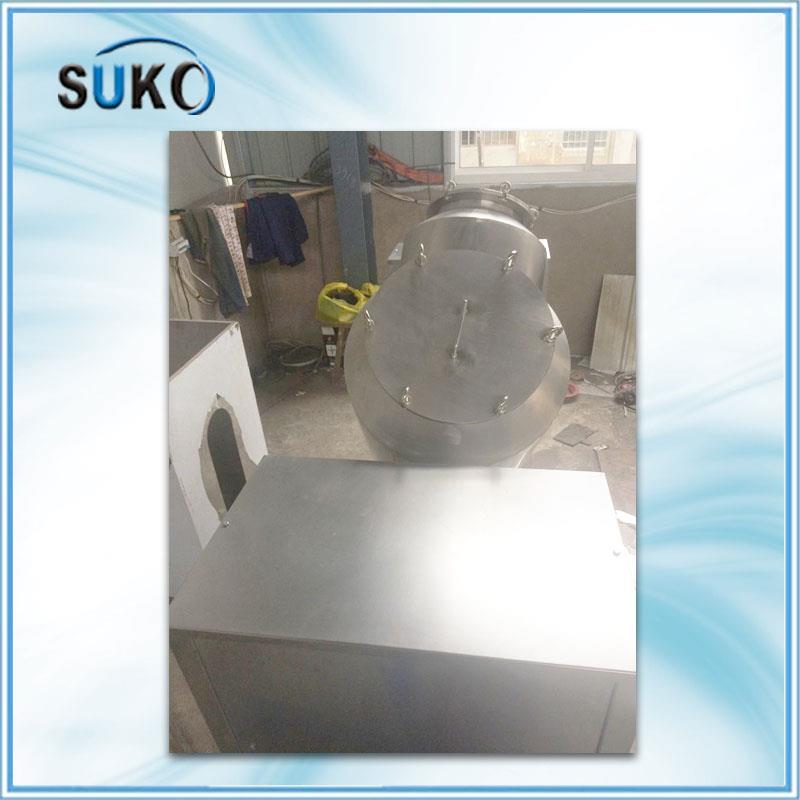

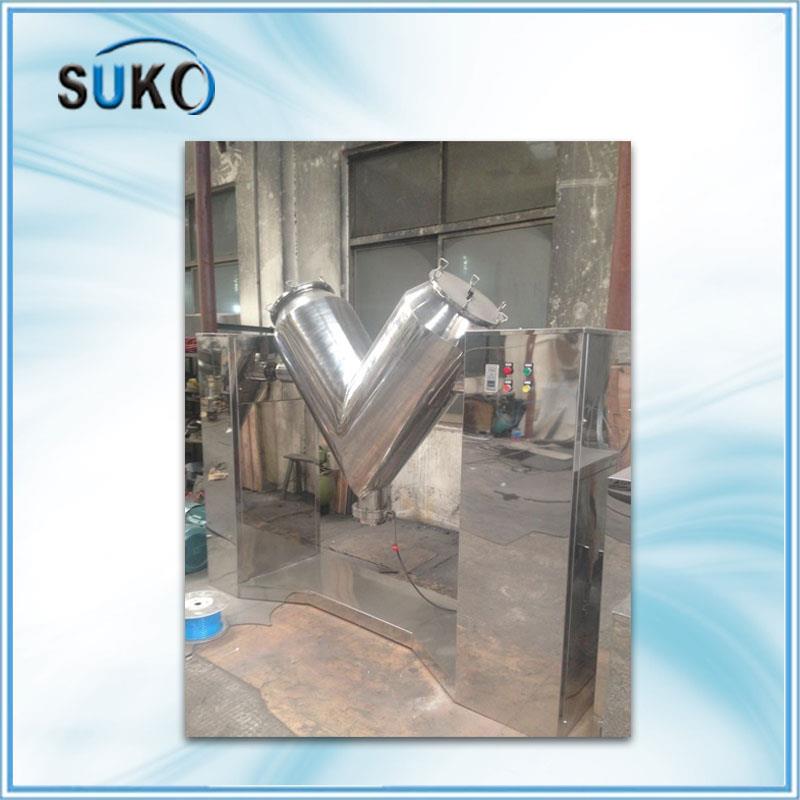

The v-100 PTFE Powder mixer

Equipment technical parameters:

1,Mixing barrel total volume of 100L, Material handling capacity: 40-50L

2, Equipment main motor power 1.5 kw.

3,Mixing time Digital setting 0-99 minutes, timing shutdown.

4,power supply: 380V/220V/50Hz.

Part 1 : Equipment OverviewEquipment name: V-type mixerEquipment model:V-100Equipment number:one setEquipment usage: For the mixture of powder

Basic requirements:

1,Each 40-50L material / batch mixing, and do not bring any impurities in the process of mixing.

2,The device barrel material is made of SUS304 stainless steel, the inside and outside of the barrel is polished, no mixing dead angle and don’t stick the material.

3,The equipment design is reasonable and advanced; with smooth operation, good reliability and simple operation; The noise is less than 65db.

Part 2: equipment performanceEquipment technical parameters:1Mixing barrel total volume of 100L, Material handling capacity: 40-50L2, Equipment main motor power 1.5 kw.3,Mixing time Digital setting 0-99 minutes, timing shutdown.4,power supply: 380V/220V/50Hz.

Main parts Technical description

1.The main motor voltage of the device is 380V, and the motor rated output power is 1.5kw.

2.The total volume of the mixing barrel is 100L, the effective volume is 50L, the standard loading is 50kg (calculated according to the material pine density 1.0), the device barrel material is made of SUS304 stainless steel, the inside and outside of the barrel is polished, no mixing dead angle and don’t stick the material. The main shaft of the barrel is installed with reinforcing plate and reinforcing bars for reinforcement treatment.

3.The frame material is steel, the bottom plate is covered with A3 steel plate so as to clean, the whole interior and exterior of the frame is smooth, the surface lining is used for rust treatment, and the surface is treated with baking paint.

4.The barrel Angle can be adjusted before discharging (adopt the electric control barrel out of the material angle). Material inlet Ф250mm, the lid with double-point single screw compression device, with good sealing performance, durable in use and easy to operate. The feed inlet adopt DN100 butterfly valve to control the material flow to ensure no dead angle.

5.The main shaft on both ends of the mixing barrel keeps the same degree of concentricity. So that the equipment runs smoothly and can avoid damage of the bearing, it also can extend the service life.

6.When mixing, the dynamic balance is good and no impact. Barrel speed is greater than or equal to 13r / min. The working noise is under 65dB.

7.The reducer adopts the cycloidal gear reducer, the motor and reducer adopt straight line, the reducer and mixing barrel adopt the sprocket drive, the transmission part adopts fully enclosed structure and has no dust pollution.

8.Mixing time digital setting (0 ~ 99 minutes), timing shutdown.

9.The electric appliances adopts People Electrical Appliance and DELIXI Electrical Appliance and the device is controlled for random control.

10.Equipment overall dimensions: 1500mm*600mm*1200mm (length*width*height).

super good

super good

get exactly what you order

get exactly what you order

good product good price good communications