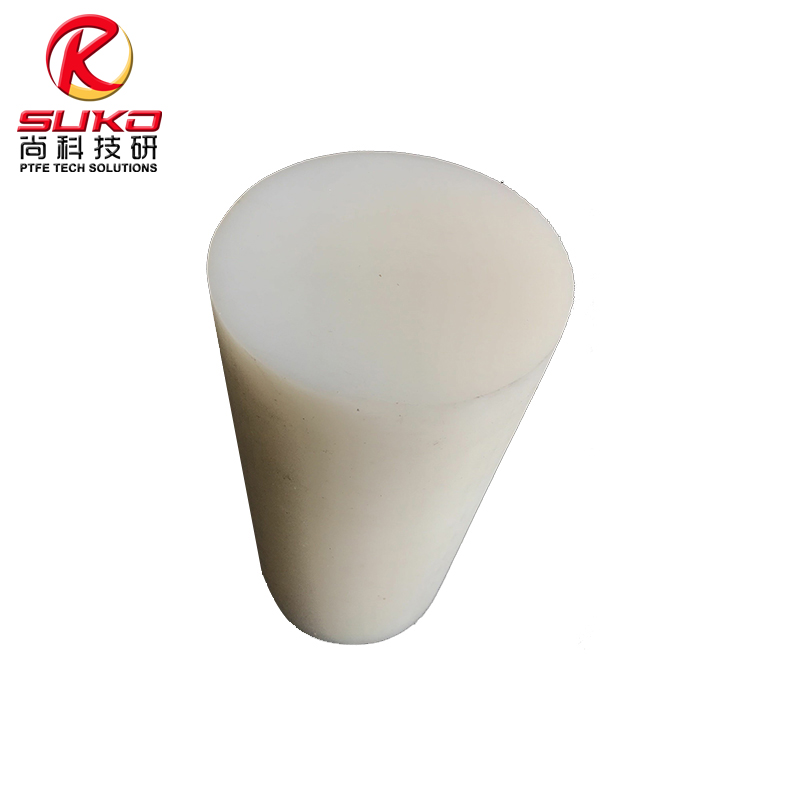

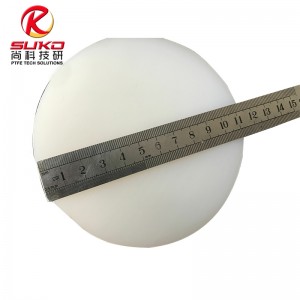

Premium UHMW Plastic Rods from GUR 4150 & 4152 for Abrasion-Resistant Applications

Product Overview

Discover our premium UHMW plastic rods crafted from high-grade GUR 4150 and GUR 4152 materials, offering unmatched abrasion resistance and low friction for superior performance in demanding industrial environments. These UHMW polyethylene rods excel in sliding applications, reducing wear and extending equipment lifespan with their self-lubricating properties.

Ideal for conveyor systems, guide rails, and food processing machinery, our abrasion resistant rods provide chemical resistance and impact strength, ensuring reliability in harsh conditions. Engineered for precision, these low friction UHMWPE rods minimize downtime and maintenance costs, making them a top choice for B2B manufacturing needs. With non-stick surfaces, they handle diverse materials effortlessly, boosting operational efficiency.

As a leading provider, SUKO specializes in high-quality GUR 4150 rods and similar products, ensuring top-tier materials for your industrial requirements. Visit our website at https://www.sukoptfe.com for more details.

Key Features

- Exceptional Abrasion Resistance: Our UHMW plastic rods from GUR 4150 and 4152 offer superior wear resistance, outperforming many metals in high-abrasion environments.

- Low Friction and Self-Lubricating: These low friction UHMWPE rods reduce energy consumption and prevent sticking, ideal for dynamic applications.

- High Impact Strength: UHMW polyethylene rods provide excellent toughness, resisting cracks and breaks under heavy loads.

- Chemical and Moisture Resistance: Resistant to a wide range of chemicals, acids, and moisture, ensuring longevity in corrosive settings.

- Non-Stick Surface: Facilitates easy material flow, reducing buildup in processing equipment.

- Temperature Tolerance: Operates effectively from -200°C to +80°C, with short-term exposure up to +120°C.

- FDA Compliance: Suitable for food contact applications, meeting safety standards for food processing.

Applications

Our abrasion resistant rods are versatile and widely used in various industries:

- Conveyor Systems: As wear strips and rollers to minimize friction and extend component life.

- Guide Rails and Chutes: In material handling to prevent jamming and reduce maintenance.

- Food Processing Machinery: For hygienic, non-contaminating parts like cutting boards and scrapers.

- Mining and Construction: In liners and bushings for heavy-duty equipment exposed to abrasives.

- Marine and Automotive: For bearings and seals requiring low friction UHMWPE properties.

- Medical and Pharmaceutical: In components needing biocompatibility and durability.

These GUR 4150 rods are engineered for precision machining, allowing custom fabrication to meet specific project needs.

Benefits

- Cost-Effective: UHMW polyethylene rods reduce replacement frequency, lowering overall operational costs.

- Eco-Friendly Options: Available in bio-based variants like GUR 4150 ECO-B, incorporating >99% bio-circular ethylene.

- Easy Machinability: Can be cut, drilled, and shaped with standard tools for custom applications.

- Noise Reduction: Dampens vibrations and noise in mechanical systems.

- Extended Service Life: Outperforms traditional materials like steel or nylon in abrasive conditions.

Why Choose SUKO?

At SUKO, we prioritize quality and customer satisfaction in providing UHMW plastic rods and other polymer solutions. Our products are sourced from premium materials like GUR 4150 and 4152 to ensure reliability. For inquiries, customization, or bulk orders, contact us via our contact page or email at info@sukoptfe.com.